Abstract of Barcodes

In 1948, a local food chain store owner approached Drexel Institute of Technology in Philadelphia asking about research into a method of automatically reading product information during checkout. Bernard Silver, a graduate student at Drexel Institute, along with fellow graduate student Norman Joseph Woodland, teamed together to develop a solution.

On October 20, 1949, Woodland and Silver succeeded in building a

working prototype describing their invention as “article

classification…through the medium of identifying patterns”. On October

7, 1952, they were granted a patent (US Patent #2,612,994) for their

“Classifying Apparatus and Method”. Efforts to develop a working system

accelerated in the 1960’s.

Bar coding was first used commercially in 1966, but to make the system acceptable to the industry as a whole there would have to be some sort of industry standard. By 1970, Logicon Inc. had developed the Universal Grocery Products Identification Code (UGPIC). The first company to produce barcode equipment for retail trade using (using UGPIC) was the American company Monarch Marking (1970), and for industrial use, the British company Plessey Telecommunications (1970).

In 1972, a committee was formed within the grocery industry to select a standard code to be used in the industry. IBM proposed a design, based upon the UGPIC work and similar to today’s UPC code. On April 3, 1973, the committee selected the UPC symbol (based on the IBM proposal) as the industry standard. George J. Laurer is considered the inventor of U.P.C. or Uniform Product Code

Introduction

Bar coding was first used commercially in 1966, but to make the system acceptable to the industry as a whole there would have to be some sort of industry standard. By 1970, Logicon Inc. had developed the Universal Grocery Products Identification Code (UGPIC). The first company to produce barcode equipment for retail trade using (using UGPIC) was the American company Monarch Marking (1970), and for industrial use, the British company Plessey Telecommunications (1970).

In 1972, a committee was formed within the grocery industry to select a standard code to be used in the industry. IBM proposed a design, based upon the UGPIC work and similar to today’s UPC code. On April 3, 1973, the committee selected the UPC symbol (based on the IBM proposal) as the industry standard. George J. Laurer is considered the inventor of U.P.C. or Uniform Product Code

Introduction

A barcode is an optical machine-readable representation of data.

Originally, barcodes represented data in the widths (lines) and the

spacings of parallel lines, and may be referred to as linear or 1D (1

dimensional) barcodes.

They also come in patterns of squares, dots, hexagons and other geometric patterns within images termed 2D (2 dimensional) matrix codes. Although 2D systems use symbols other than bars, they are generally referred to as barcodes as well. Barcodes can be read by optical scanners called barcode readers, or scanned from an image by special software.

The primary barcode used in the United States is the UPC (Universal Product Code) barcode. The UPC is also the "original" barcode. The UPC was designed for the grocery industry. Because of the large number of items normally "checked-out" at the grocery store, a method was needed to speed up and eliminate "human" cashier errors. In 1973, the UPC barcode was born.

To the average person, the barcode looks confusing and complex, but to a "bar-coded" friendly computer, it's actually very simple

Bar codes can be thought of as a printed type of the Morse code with narrow bars (and spaces) representing dots, and wide bars representing dashes.

A bar code reader decodes a bar code by scanning a light source across the bar code and measuring the intensity of light reflected back by the white spaces. The pattern of reflected light is detected with a photodiode which produces an electronic signal that exactly matches the printed bar code pattern. This signal is then decoded back to the original data by inexpensive electronic circuits.

Due to the design of most bar code it does not make any difference if you scan a bar code from right to left or from left to right.

There are a variety of different types of bar code encoding

schemes, each of which were originally developed to full fill a specific

need in a specific industry.

There are a variety of different types of bar code encoding

schemes, each of which were originally developed to full fill a specific

need in a specific industry.

The different symbologies have different capabilities for encoding data. For example the UPC symbology used to identify retail products always contains 12 numeric digits.

These type of bar codes are called "linear symbologies" because they are made up of a series of lines of different widths. Most commercially available bar code scanners are able to read all of the different linear bar code symbologies therefore you do not need different readers for different types of bar codes.

New "2-Dimensional" bar code symbologies like EAN, Aztec Code etc. are also now available that can encode several thousand bytes of data in a single bar code symbol including text or binary data. The newer 2D bar code symbologies typically require special bar code readers that are designed specifically for reading them.

The allowable magnification range depends on the symbol type and the intended scanning environment. Reliability of scanning is always enhanced by selecting a magnification higher than the minimum.

To print an accurate and high quality bar code symbol a number of factors, such as the printing process, ink quality, and substrate, must be taken into consideration.

Any obstruction or reduction in the Quiet Zones will most likely result in scanning difficulties.

The minimum size required for the Quiet Zones depends on the magnification of the bar code symbol.

It is recommended to allow slightly more than the minimum required Quiet Zones to allow for any possible ink spread or plate registration issues.

As a result, some colour combinations and ink types are unsuitable for scanning because they do not provide sufficient contrast between the dark bars and the light background, or they provide a much too high reflectance value.

The most suitable and reliable colour combination is black bars on a white background.

However, as a general rule, the background of the bar code symbol can be a light, warm colour that does not contain any black (such as yellow or light orange), and the bar colour can be a dark, cool colour that has no, or low, red content (such as dark blue or dark green).

This is especially evident on transparent and translucent packages where the background is not printed.

For printing bar code symbols it is recommended that you avoid the following:

• High gloss substrates

• Transparent or semi-transparent backgrounds

• Transparent wrappers over the printed bar code symbol if necessary to print onto a highly reflective (flexible) substrate, we recommend the following:

• Increase the magnification of the bar code symbol to between 105% and 120% (X-dimension 0.35mm - 0.40mm)

• Increase the amount of Bar Width Reduction

• Make the background of the symbol as dense and less reflective as possible. To do this you may try the following:

• If you are not using wet inks, print two background layers. This may be two layers of the one colour, or you may use all light colours in the print run (e.g. white and yellow)

• Use a less viscous ink that will provide maximum coverage and density

Maintaining acceptable print quality and consistent print gain (ink spread) requires regular ongoing checks.

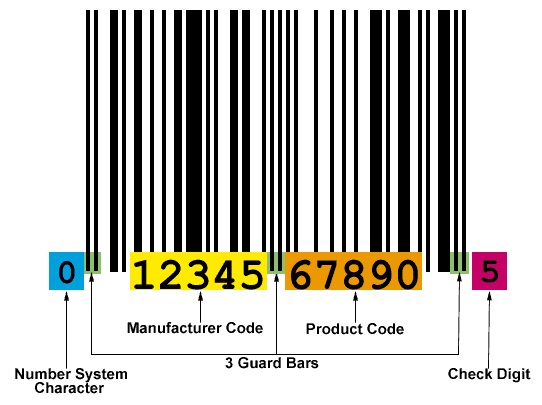

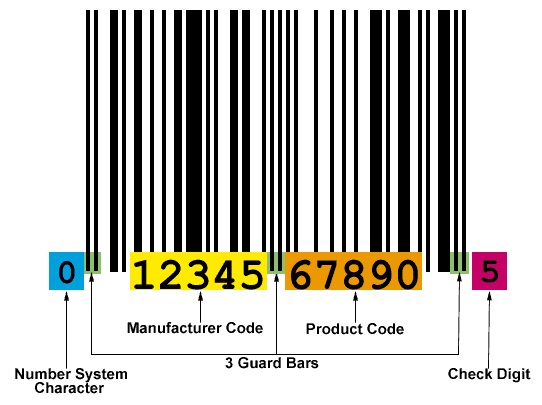

This number is a UPC system number that characterizes specific

types of barcodes. In a UPC barcode it is normally on the left of the

barcode. The actual "barcode" (the "bars" and "spaces") is the first

"barcode" after the first "guard bar". The Number System Character is

the blue box on the "Anatomy of a Barcode".

This number is a UPC system number that characterizes specific

types of barcodes. In a UPC barcode it is normally on the left of the

barcode. The actual "barcode" (the "bars" and "spaces") is the first

"barcode" after the first "guard bar". The Number System Character is

the blue box on the "Anatomy of a Barcode".

• 1 - Reserved.

• 2 - Random weight items like fruits, vegetables, and meats, etc.

• 3 - Pharmaceuticals

• 4 - In-store code for retailers.

• 5 - Coupons

• 6 - Standard UPC number.

• 7 - Standard UPC number.

• 8 - Reserved.

• 9 - Reserved

Almost every item purchased from a grocery store, department store, and mass merchandiser has a UPC barcode on it. This greatly helps in keeping track of a large number of items in a store and also reduces instances of shoplifting involving price tag swapping, although shoplifters can now print their own barcodes.

The tracking of item movement, including rental cars, airline luggage, nuclear waste, mail and parcels.

Entertainment event tickets can have barcodes that need to be validated before allowing the holder to enter sports arenas, cinemas, theatres, fairgrounds, transportation etc. This can allow the proprietor to identify duplicate or fraudulent tickets more easily

They also come in patterns of squares, dots, hexagons and other geometric patterns within images termed 2D (2 dimensional) matrix codes. Although 2D systems use symbols other than bars, they are generally referred to as barcodes as well. Barcodes can be read by optical scanners called barcode readers, or scanned from an image by special software.

The primary barcode used in the United States is the UPC (Universal Product Code) barcode. The UPC is also the "original" barcode. The UPC was designed for the grocery industry. Because of the large number of items normally "checked-out" at the grocery store, a method was needed to speed up and eliminate "human" cashier errors. In 1973, the UPC barcode was born.

To the average person, the barcode looks confusing and complex, but to a "bar-coded" friendly computer, it's actually very simple

Bar Codes Basic

Bar codes provide a simple and inexpensive method of encoding text

information that is easily read by inexpensive electronic readers.

Bar coding also allows data to be collected rapidly and with extreme

accuracy. A bar code consists of a series of parallel, adjacent bars

and spaces. Predefined bar and space patterns are used to encode small

strings of character data into a printed symbol. Bar codes can be thought of as a printed type of the Morse code with narrow bars (and spaces) representing dots, and wide bars representing dashes.

A bar code reader decodes a bar code by scanning a light source across the bar code and measuring the intensity of light reflected back by the white spaces. The pattern of reflected light is detected with a photodiode which produces an electronic signal that exactly matches the printed bar code pattern. This signal is then decoded back to the original data by inexpensive electronic circuits.

Due to the design of most bar code it does not make any difference if you scan a bar code from right to left or from left to right.

The basic structure of a bar code consists of a

leading and trailing quiet zone, a start pattern, one or more data

characters, optionally one or two check characters and a stop pattern

The different symbologies have different capabilities for encoding data. For example the UPC symbology used to identify retail products always contains 12 numeric digits.

These type of bar codes are called "linear symbologies" because they are made up of a series of lines of different widths. Most commercially available bar code scanners are able to read all of the different linear bar code symbologies therefore you do not need different readers for different types of bar codes.

New "2-Dimensional" bar code symbologies like EAN, Aztec Code etc. are also now available that can encode several thousand bytes of data in a single bar code symbol including text or binary data. The newer 2D bar code symbologies typically require special bar code readers that are designed specifically for reading them.

Bar Code Symbol Characteristics

1. Magnification

The magnification (size) of the bar code symbol is determined by

the X-dimension (one narrow module width) in relation to a nominal size.The allowable magnification range depends on the symbol type and the intended scanning environment. Reliability of scanning is always enhanced by selecting a magnification higher than the minimum.

To print an accurate and high quality bar code symbol a number of factors, such as the printing process, ink quality, and substrate, must be taken into consideration.

2. Bar Height

Once the magnification of the bar code symbol has been determined,

for EAN/UPC Bar Code symbols it is important to ensure that the height

remains in proportion to the magnification, and does not drop below the

minimum specified.

3. Quiet Zones (Light Margins)

The Quiet Zones (Light Margin) of the bar code symbol are the

solid, light areas before the first bar and after the last bar. These

areas are extremely important as they allow the scanner to recognise the

beginning and end of the bar code symbol. Any obstruction or reduction in the Quiet Zones will most likely result in scanning difficulties.

The minimum size required for the Quiet Zones depends on the magnification of the bar code symbol.

It is recommended to allow slightly more than the minimum required Quiet Zones to allow for any possible ink spread or plate registration issues.

4. Colours

The colours and type of ink you choose for your bar code symbols is

very important. As a scanner reads a bar code symbol using an infrared

light source it sees the symbol differently to the human eye. As a result, some colour combinations and ink types are unsuitable for scanning because they do not provide sufficient contrast between the dark bars and the light background, or they provide a much too high reflectance value.

The most suitable and reliable colour combination is black bars on a white background.

However, as a general rule, the background of the bar code symbol can be a light, warm colour that does not contain any black (such as yellow or light orange), and the bar colour can be a dark, cool colour that has no, or low, red content (such as dark blue or dark green).

5. Substrate

The substrate (the material the bar code symbol is printed on) is

very important. If unsuitable this can cause scanning difficulties.

Different packaging materials reflect light differently, which can have

an effect on the scanning ability of the bar code symbol. This is especially evident on transparent and translucent packages where the background is not printed.

For printing bar code symbols it is recommended that you avoid the following:

• High gloss substrates

• Transparent or semi-transparent backgrounds

• Transparent wrappers over the printed bar code symbol if necessary to print onto a highly reflective (flexible) substrate, we recommend the following:

• Increase the magnification of the bar code symbol to between 105% and 120% (X-dimension 0.35mm - 0.40mm)

• Increase the amount of Bar Width Reduction

• Make the background of the symbol as dense and less reflective as possible. To do this you may try the following:

• If you are not using wet inks, print two background layers. This may be two layers of the one colour, or you may use all light colours in the print run (e.g. white and yellow)

• Use a less viscous ink that will provide maximum coverage and density

6. Bar Widths and Print Quality

Always ensure that the print quality of the bar code symbol is of a

high standard. Ensure that the bars in the symbol are clearly defined,

watch for voids or smudging, and avoid flecks in the background colour.Maintaining acceptable print quality and consistent print gain (ink spread) requires regular ongoing checks.

Anatomy of Barcodes

Codes of the Number System Character:

• 0 - Standard UPC number. • 1 - Reserved.

• 2 - Random weight items like fruits, vegetables, and meats, etc.

• 3 - Pharmaceuticals

• 4 - In-store code for retailers.

• 5 - Coupons

• 6 - Standard UPC number.

• 7 - Standard UPC number.

• 8 - Reserved.

• 9 - Reserved

Conclusion and Future Scope

Barcodes — especially the UPC — have slowly become an essential

part of modern civilization. Their use is widespread, and the technology

behind barcodes is constantly improving. Some modern applications of

barcodes include:Almost every item purchased from a grocery store, department store, and mass merchandiser has a UPC barcode on it. This greatly helps in keeping track of a large number of items in a store and also reduces instances of shoplifting involving price tag swapping, although shoplifters can now print their own barcodes.

The tracking of item movement, including rental cars, airline luggage, nuclear waste, mail and parcels.

Entertainment event tickets can have barcodes that need to be validated before allowing the holder to enter sports arenas, cinemas, theatres, fairgrounds, transportation etc. This can allow the proprietor to identify duplicate or fraudulent tickets more easily

References

• Automating Management Information Systems: Barcode Engineering

and Implementation – Harry E. Burke, Thomson Learning, ISBN

0-442-20712-3• Automating Management Information Systems: Principles of Barcode Applications – Harry E. Burke, Thomson Learning, ISBN 0-442-20667-4

• The Bar Code Book – Roger C. Palmer, Helmers Publishing, ISBN 0-911261-09-5, 386 pages

• The Bar Code Manual – Eugene F. Brighan, Thompson Learning, ISBN 0-03-016173-8

• Handbook of Bar Coding Systems – Harry E. Burke, Van Nostrand Reinhold Company, ISBN 978-0-442-21430-2, 219 pages

No comments:

Post a Comment